|

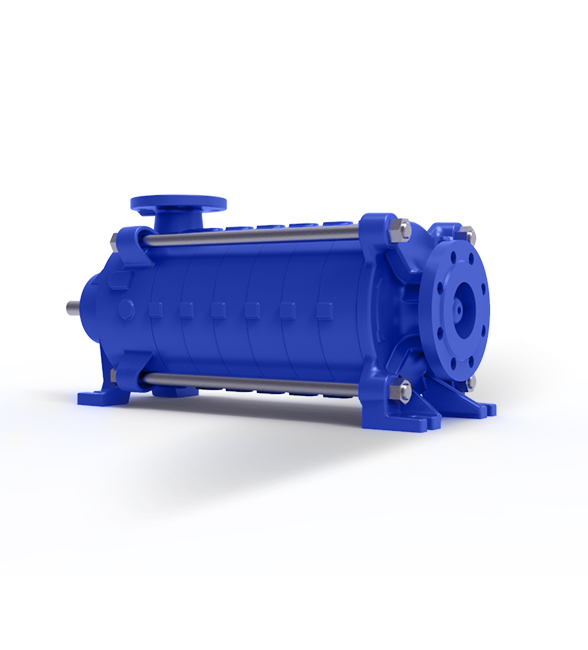

-Centrifugal pumps with horizontal shaft, split body, diffuser, multistage, closed impeller.

-11 models from DN 25 to DN 250 discharge flange diameter.

-Suction flanges according EN 1092 - 2 / PN 16 and discharge flanges to EN 1092 - 2 / PN 40 (PN 63). (flanges in pumps with stainless steel body material according to EN 1092-1 standard pressure class.)

-In standard production, the suction flange is on the coupling side and on the right side, the discharge flange at the other end and top (R 4/2). If flange positions other than standard manufacture are required, this request must be specified at the time of order.

-All impellers are balanced dynamically or statically in accordance with ISO 1940 class 6.3.

-Axial force is balanced by impeller balancing holes system.

-The direction of rotation is clockwise when viewed from the motor side.

-ARS type pumps use “grease lubricated” bearings as standard.

|

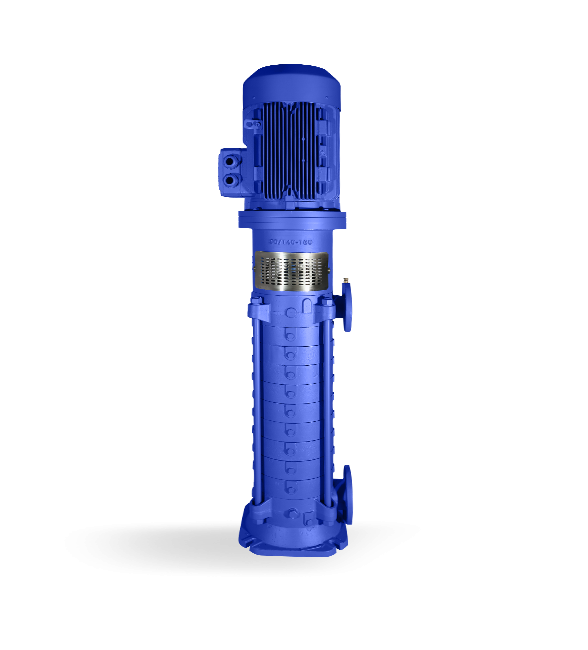

-Horizontal shaft, split body, diffuser, multistage, closed impeller centrifugal pumps. 2 models from DN 40 to DN 50 discharge flange diameter.

-ARS-KC type pumps have long bearing life due to the opposite impeller design.

-Suction flanges comply with TS EN 1092 - 2 / PN 16 and discharge flanges comply with TS EN 1092 - 2 / PN 40. (Flanges in pumps with stainless steel body material comply with TS EN 1092 - 1 standard related pressure class.)

-In standard manufacturing, the suction flange is on the coupling side and on the right side, the discharge flange is on the other end and top (R 4/2).

-If flange positions other than standard manufacturing are desired, this request must be specified at the time of order.

-All impellers are balanced dynamically or statically in accordance with ISO 1940 class 6.3.

-Axial force is balanced with impeller balancing holes system.

-The direction of rotation is clockwise when viewed by the engine.

-ARS-KC type pumps use “grease-lubricated” bearings as standard.

|