|

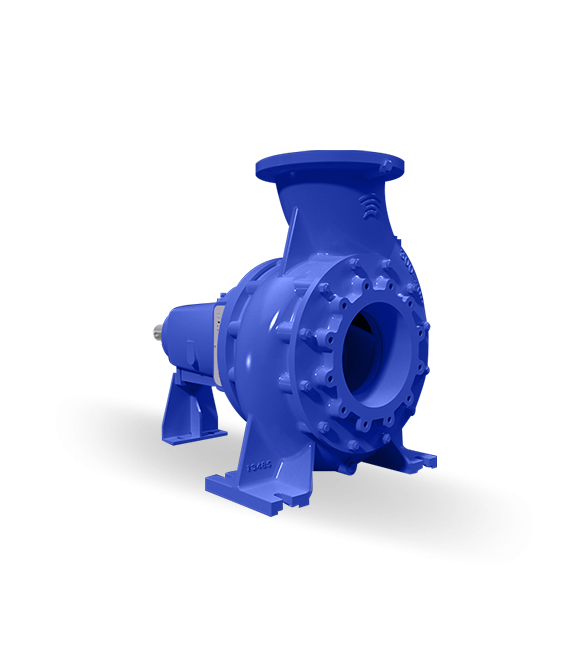

-Horizontal, radially split volute casing type, single stage, end suction centrifugal pumps with closed or semi-open impeller.

-In addition to 29 basic sizes conforming with ISO 2858, there are 10 additional sizes. Dimensions of additional sizes may dier from other suppliers.

-Heavy duty shaft not in touch with the medium handled (dry shaft)

-Body sealing is ensured by flat gaskets that are not displaced under pressure.

-Suction and discharge flanges conform to EN 1092-2 / PN 16. (EN 1092-1 / PN 16 for steel or stainless steel casing)

-Due to the back-pull-out design, the complete bearing assembly including impeller and casing cover can be dismantled without removing the volute casing from the pipe system. (With spacer coupling application, also possible to take out the rotor group without dismantling the electric motor.)

-All impellers are balanced dynamically or statically according to ISO 1940 class 6.3.

-For closed impellers, axial thrust is balanced by impeller balancing holes system while for semi-open impellers, it is balanced by back ribs.

-Direction of rotation is clockwise viewed from drive end.

-Bearings of TKF-AH type pumps are always oil lubricated.

|

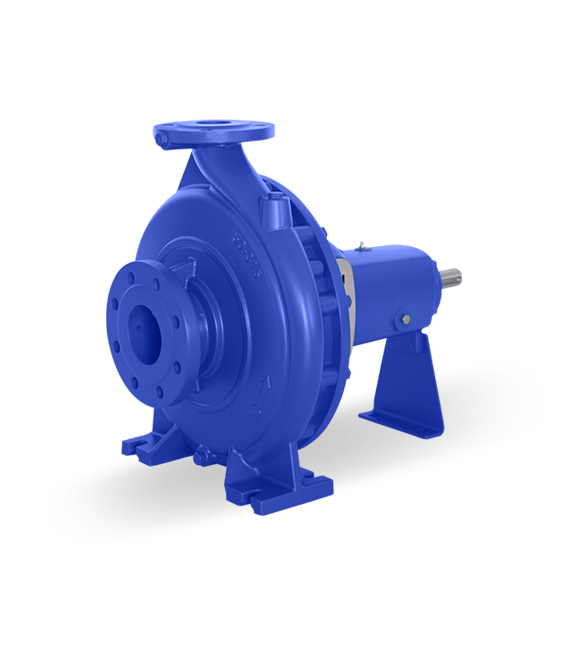

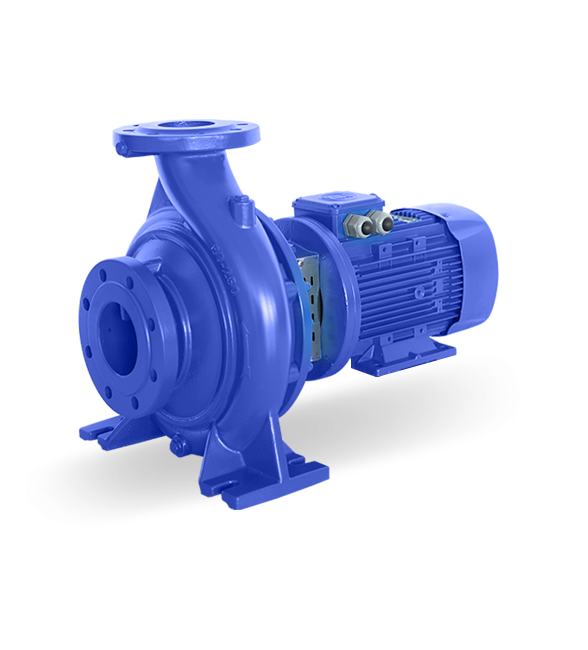

-Horizontal shaft, volute, single stage, end suction, air cooled, closed impeller centrifugal pumps.

-Suction and discharge flanges conform to EN 1092-2 / PN 16. (flanges for pumps with stainless steel body conform to EN 1092 - 1 / PN 16)

-With the detachable design of the pump, it is possible to remove the bearing assembly, the seal bearing, the pump shaft and the impeller without removing the snail from the pipe. (Optionally, the rotor group of the pump can be removed without removing the motor from the motor carrier by applying the spacer sleeve coupling).

-All impellers are balanced dynamically or statically in accordance with ISO 1940 class 6.3.

-The direction of rotation is clockwise when viewed from the motor side.

-The axial force is compensated by the balancing vanes on the rear of the impeller.

-TKF-K type pumps use “oil lubrication” bearings as standard.

|